CMC Technologies New Zealand

CMC Technologies (CMC) has been supporting New Zealand industries since 1999, supplying high-quality industrial instrumentation from our Sydney base. We partner with leading manufacturers from Europe, the UK, USA, South Korea, Japan, and China, providing trusted solutions for Explosion Protection, Pressure Relief, Fire Safety, Flow Monitoring, Process Vision, and Instrumentation.

Our Sydney warehouse, conveniently located near Sydney Airport, allows us to efficiently dispatch stock to customers across New Zealand. We offer a wide selection of products, including:

- IEP Brilex explosion vents and detection sensors

- Hoerbiger EVN flameless explosion relief valves

- FDC rupture discs

- IEP Technologies explosion suppression and isolation systems

- Lumiglas sight glasses and luminaires

- KITO flame arresters and pressure relief valves

- Metaglas metal fused sight glasses

- Advanced Couplings sanitary clamps and ferrules

- Sparksafe and Alptec static earthing clamps, cables, and grounding systems

- Fixed and portable CMC ultrasonic flow meters

- Smartmeasurement flow meters

- T&D temperature and humidity data loggers

- Comet sensors for temperature, humidity, CO₂, dew point, atmospheric pressure, as well as dataloggers and transmitters and many more

If a specific item is not available in our Sydney stock, we source directly from our global suppliers and ship directly to New Zealand. Delivery times vary depending on manufacturer availability and product type.

Our team includes qualified Chemical and Mechatronic Engineers who provide technical support and advice to clients throughout New Zealand. For reliable instrumentation solutions and expert assistance, CMC Technologies is ready to help.

Global Brand Distributor

CMC proudly distributes a curated selection of trusted global brands, known for their quality and reliability in the industrial instrumentation. Our partnerships allow us to offer our customers premium products backed by local expertise and support.

CMC Technologies’ 26 Years Celebration

CMC Technologies celebrates 26 years! It was on January 25, 1999, that CMC Technologies was founded.

A special thanks from Managing Director, Con Carpis

I extend my gratitude to our customers, manufacturers, and employees who have played a vital role in our success over the past quarter-century in Australia and New Zealand. Throughout the last 2.5 decades, we have navigated challenges such as stock market crashes and pandemics. I take personal satisfaction in knowing that our company has been instrumental in assisting numerous businesses with innovative solutions in process instrumentation. Furthermore, we’ve contributed to saving lives and safeguarding infrastructure through the supply of products and systems dedicated to explosion prevention, protection, and pressure relief.

A sincere thank you to everyone who has been part of this remarkable journey. We eagerly anticipate our future growth.

IEP Technologies Unites Brilex and Hoerbiger Safety Solutions

Brilex Explosion Vents and Hoerbiger EVN 2.0/3.0 Explosion Relief Valves are now unified under IEP Technologies – Hoerbiger Safety Solutions.

CMC Technologies leverages over 20 years’ experience distributing Brilex products in Australia and New Zealand, and now also manages Hoerbiger EVN sales globally.

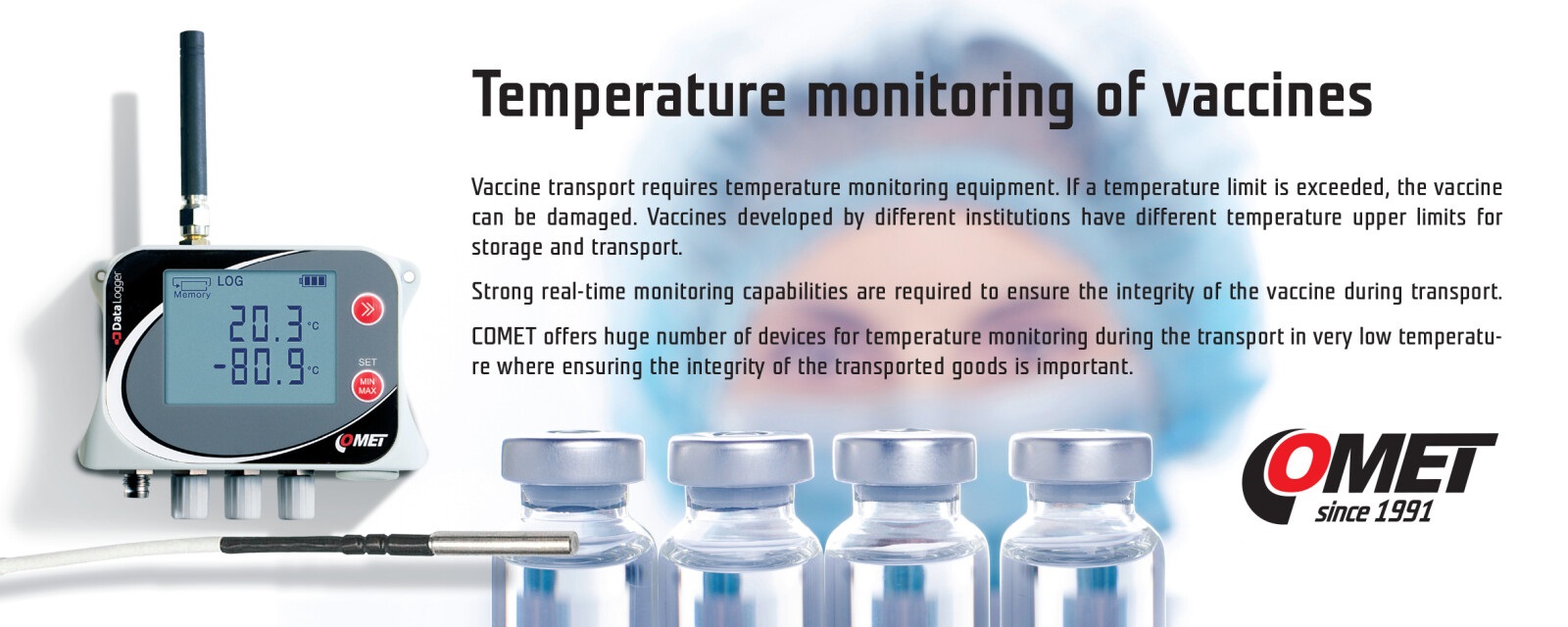

Vaccine Monitoring That Protects What Matters For New Zealand Businesses

At CMC Technologies, we specialise in high-quality vaccine monitoring data loggers. Keeping vaccines at safe temperatures isn’t just important – it’s critical. Different vaccines need different temperature ranges during storage and transport, which is why real-time monitoring is essential. It lets you act instantly if temperatures change, protecting vaccine integrity every step of the way.

Get in touch to learn how our vaccine monitoring solutions can safeguard your valuable stock.

Please find out more about vaccine monitoring data loggers by contacting us.

Explosion Protection

Protecting New Zealand Workplace from Dust Explosions

When dust builds up in industrial settings across New Zealand, it can create potentially catastrophic explosion hazards that threaten both your property and your people. At CMC Technologies, we understand the unique challenges Kiwi businesses face and provide tailored solutions to keep your operations safe.

Our comprehensive dust explosion protection includes several critical systems designed specifically for NZ industrial environments:

Explosion venting offers a reliable first line of defense by safely redirecting blast pressure away from personnel and equipment. For more immediate threats, our explosion suppression systems deploy food-safe or inert chemicals to quickly extinguish explosions before they can escalate.

To stop explosions from spreading throughout your facility, we implement both passive and active isolation systems that contain incidents to their point of origin. Our complete safety approach also includes:

- Flame arresters

- Smolder detection technolog

- Static earthing solutions

- Spark detection and extinguishing systems

- Emergency inerting capabilities

Understanding your specific risks is essential. That’s why we offer thorough dust explosibility testing (analysing Pmax, Kst, MIE, and MEC values) to identify potential hazards in your particular processes. This scientific approach allows us to design and implement the most effective prevention and protection measures for your facilities in New Zealand.

Don’t wait for a disaster to highlight your vulnerabilities. Connect with our team of experts who understand NZ workplace safety requirements and can help safeguard your business against dust explosion risks.

Pressure Relief

Keeping New Zealand Industries Safe with Pressure Relief Solutions

Every pressurised system in New Zealand needs reliable protection against overpressure. That’s why CMC Technologies provides specialised pressure relief solutions designed to meet local safety standards and keep your operations running safely.

We understand that safety isn’t one-size-fits-all. Our range includes rupture discs, pressure relief valves, vacuum relief valves, emergency relief vents, railway tankers valves, sanitary pressure and vacuum relief valves, nitrogen (N2) tank blanketing system and pseudo pin relief valves – all engineered for instant, safe pressure release when you need it most. Whether you’re in manufacturing, processing, or any industry handling pressurised systems, we’ve got you covered.

Why Standards Matter for NZ Businesses

Compliance isn’t just paperwork – it’s critical protection. Our solutions align with key standards recognised across New Zealand and internationally, including:

- AS 1210 (Pressure Vessels)

- AS 1358 (Non-Fired Pressure Vessels)

- ISO 6718 (Bursting Disc Safety Devices)

- ASME VIII (Pressure Vessel Construction)

Tailored Protection for Your Site

We don’t just supply equipment; we deliver peace of mind. Our team helps you select the right pressure relief devices for your specific application, ensuring they integrate seamlessly with your existing systems and meet NZ safety requirements.

Ready to Secure Your Systems?

Talk to our specialists about pressure relief solutions that protect your people, plant, and productivity. We’ll help you navigate the standards and find the right fit for your operation.

Fire Protection

Complete Fire Protection for New Zealand Workplaces

At CMC Technologies, we understand that fire safety isn’t just about fighting flames – it’s about preventing them before they start. That’s why we offer a full suite of fire protection solutions designed specifically for New Zealand’s industrial environments.

Our Fire Safety Range Covers Every Stage:

Prevention & Early Detection

- T and B Electronic Spark Detection Systems: Catch dangerous sparks in your process lines before they ignite

- Robecco Smouldering Fire Detection: Specialised CO monitoring for spray dryers and other critical equipment where hidden fires can start

Active Protection

- KITO Flame Arresters: Stop flames in their tracks by preventing fire from traveling through pipelines

- Robecco-Yarra Emergency Inerting: Rapidly displace oxygen with inert gas to suppress fires before they spread

Post-Incident Control

- IEP Technologies Post-Explosion Fire Protection: Contain secondary fires and prevent chain reactions after an explosion event

Why Kiwi Businesses Trust Us

We don’t just sell equipment – we deliver integrated fire safety solutions tailored to your specific industry. Whether you’re in food processing, chemical manufacturing, or any sector with fire risks, our systems work together to:

- Protect your people and plant

- Minimise costly downtime

- Meet NZ safety standards

Ready to Strengthen Your Fire Defences?

Talk to our team about designing a fire protection system that covers every risk point in your operation. We’ll help you select the right combination of spark detection, flame arresters, and suppression technology for your workplace.

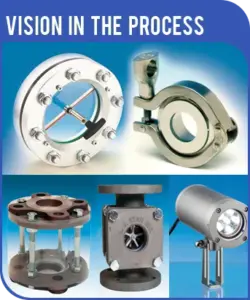

Vision in the Process

Clear Views Inside Your Vessels & Pipelines – The Kiwi Way

When you’re monitoring vessels and pipelines in your New Zealand operation, seeing what’s happening inside is critical. Poorly lit tanks or complex piping systems can hide potential problems – that’s where the right observation equipment makes all the difference.

What You Need for Clear Visibility

- Sight glasses & discs: Your window into vessels and pipelines

- Sight flow indicators: Track fluid movement at a glance

- Vessel cameras: Get eyes on hard-to-reach areas without opening the system

- Level gauges: Monitor fluid levels accurately and safely

Light Up Dark Spaces

Many vessels – especially storage tanks and reactors – are naturally dark inside. Our sight glass lights and luminaires cut through the gloom, giving your team clear visibility for inspections and monitoring. No more guessing what’s happening in those shadowy corners.

Specialised Solutions for Hygienic Industries

For New Zealand’s food processing, dairy, pharmaceutical, and biotech sectors, contamination control is non-negotiable. We provide sanitary/aseptic fittings built to the highest standards:

- Pharmaceutical-grade tri-clamp connections

- Stainless steel ferrules and gaskets

- Hygienic sight glasses and indicators designed for clean-in-place (CIP) systems

Why Kiwi Operations Trust CMC Technologies

We don’t just supply parts – we deliver complete visibility solutions tailored to your industry. Whether you’re running a Waikato dairy plant, an Auckland pharmaceutical lab, or a Christchurch manufacturing facility, we understand NZ’s unique compliance requirements and operational challenges.

Ready to Improve Your Process Visibility?

Talk to our expert team about sight glasses, lighting systems, cameras, and sanitary fittings designed specifically for Kiwi conditions. We’ll help you select the right combination to keep your processes visible, safe, and compliant.

Flow Measurement

Get Accurate Flow Measurement for Every New Zealand Process

When you need to measure liquids, gases, or steam in your New Zealand operation, getting it right matters. Different processes demand different approaches – that’s why CMC Technologies offers a full range of flow measurement solutions tailored to your specific needs.

Two Ways to Measure Flow

We supply both volumetric flowmeters (measuring how much space the fluid occupies) and mass flowmeters (measuring the actual weight of the fluid moving through). The right choice depends entirely on your process requirements.

Our Flow Meter Technologies – Built for NZ Conditions

Whatever you’re measuring, we’ve got the right technology for the job:

For Precision Mass Flow

- Coriolis mass-flow meters: Gives you both mass flow and density in one device

- Thermal mass flow meters: Ideal for clean gases and compressed air systems

For Differential Pressure Measurement

- Orifice plates: Simple, reliable solution for many liquid and gas applications

- Delta-tubes & averaging pitot tubes: Great for large pipes and ducts

- Venturi meters: Low permanent pressure loss for sensitive systems

- Cone meters: Handles dirty fluids and wide flow ranges

For Conductive Liquids

- Electromagnetic flowmeters (magnetic flowmeters): No moving parts – perfect for water, wastewater, and slurries

For Open Channels & Weirs

- Open-channel flow meters: Essential for irrigation, water treatment, and environmental monitoring

For High-Accuracy Volume Measurement

- Positive displacement flow meters: Unmatched precision for custody transfer and batching

- Turbine flow meters: Reliable for clean liquids and gases

- Ultrasonic flow meters: Non-intrusive measurement – clamp-on options available

For Simple Visual Indication

- Variable area flow meters (rotameters): Instant visual flow rate at a glance

For Vortex Sensing

- Vortex flow meters: Robust solution for steam, gas, and liquid flow

Specialised Protection

- Thermal flow switches & level switches: Automated safety for critical processes

Why Kiwi Operations Choose Us

We don’t just sell flow meters – we deliver measurement confidence. Whether you’re running a dairy processing plant in Canterbury, a chemical facility in Taranaki, or a water treatment operation in Auckland, we understand:

- NZ’s unique compliance requirements

- The challenges of measuring everything from milk to methane

- The need for reliable, low-maintenance solutions

Need Help Choosing the Right Flow Meter?

Talk to our flow measurement specialists. We’ll help you select the perfect technology for your process, fluid type, and accuracy requirements – ensuring you get reliable data you can trust.

Process Instrumentation

Complete Process Instrumentation Source for New Zealand Industries

When you need reliable measurement and control equipment in New Zealand, CMC Technologies has you covered. We supply essential instruments for pressure, temperature, humidity, and air quality – plus the calibration services to keep them compliant.

Pressure Solutions You Can Trust

- Differential Pressure Gauges (DP Gauges): Monitor filter efficiency, flow rates, and system balance

- Differential Pressure Switches (DP Switches): Automated alerts when pressure thresholds are reached

- Differential Pressure Transmitters (DP Transmitters): Precise, continuous monitoring for process control

- Standard Pressure Gauges & Switches: Simple, dependable pressure monitoring for everyday applications

Backflow Prevention – Critical for NZ Water Safety

- Backflow Test Kits: Complete kits for testing prevention valves in water systems

- Annual Calibration Checks & Certificates: Stay compliant with NZ water safety regulations with our certified calibration service

Temperature & Humidity Monitoring

- Temperature Data Loggers: Track thermal conditions in storage, transport, and processes

- Temperature Transmitters: Real-time temperature data for control systems

- Humidity Data Loggers: Essential for controlled environments like food storage and labs

- Humidity Transmitters: Continuous moisture monitoring for critical processes

Advanced Data Logging

- Voltage Data Loggers: Monitor electrical systems and equipment performance

- Wireless Data Loggers: Remote monitoring without wiring hassles – ideal for hard-to-reach NZ sites

Air Quality & Process Control

- Air Filters: Protect equipment and processes from airborne contaminants

- Air Dryers: Prevent moisture damage in compressed air systems

- On-line Liquid Analysers: Real-time monitoring of water quality, chemical concentrations, and process fluids

Why Kiwi Industries Choose CMC Technologies

We’re not just suppliers – we’re your NZ instrumentation partners. We understand:

- The importance of compliance with NZ standards (especially for water safety)

- The challenges of harsh environments from Northland factories to Southland processing plants

- The need for reliable, low-maintenance solutions that keep your operations running smoothly

Need Help Selecting or Maintaining Your Instruments?

Talk to our expert team about pressure instruments, calibration services, data loggers, or air quality equipment. We’ll help you find the right solutions for your specific application and ensure they stay accurate and compliant year after year.